Solar Panel Photovoltaic Module

Working Principle

When sunlight irradiates the solar panel made of semiconductor materials, the photon energy is transferred to the electrons in the semiconductor, causing the electrons to transition into free electrons and form an electric current, thereby directly converting solar energy into electricity through the photovoltaic effect.

Classification and Characteristics

Monocrystalline Silicon Solar Panels:

High purity silicon material, complex manufacturing process, relatively high cost.

Higher efficiency, generally around 15%-24% or even higher, long service life, good stability.

Polycrystalline Silicon Solar Panels:

Composed of multiple small monocrystalline silicon grains, relatively lower cost compared to monocrystalline silicon.

Efficiency typically 12%-15%, slightly lower photoelectric conversion efficiency, but cost-effective and widely used in the market.

Amorphous Silicon Solar Panels:

Simple manufacturing process, low cost, can be made into large-area thin-film cells.

Relatively lower photoelectric conversion efficiency, generally around 6%-10%, and poorer stability, more affected by environmental factors.

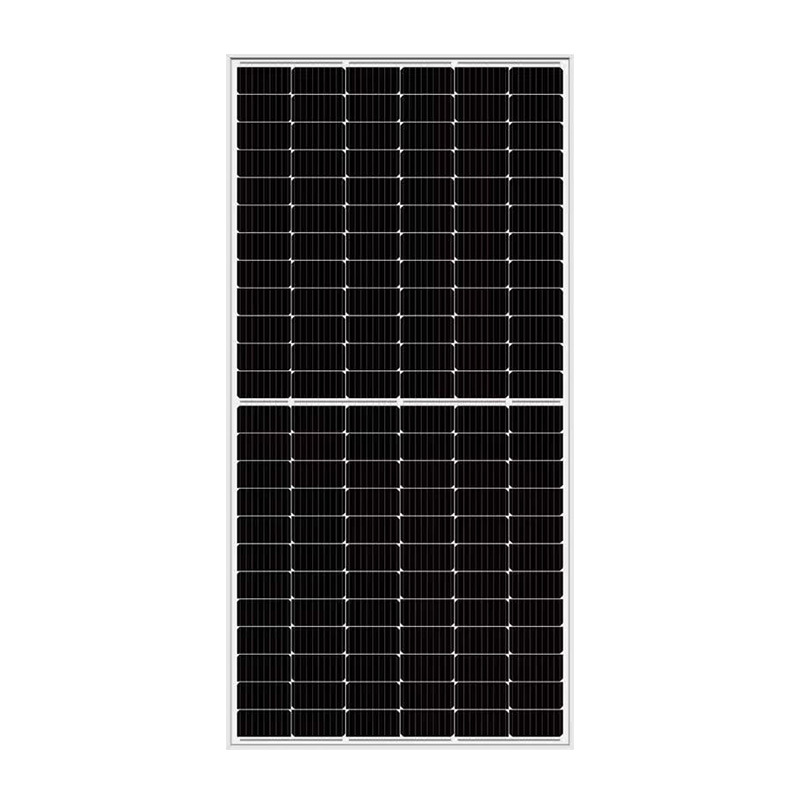

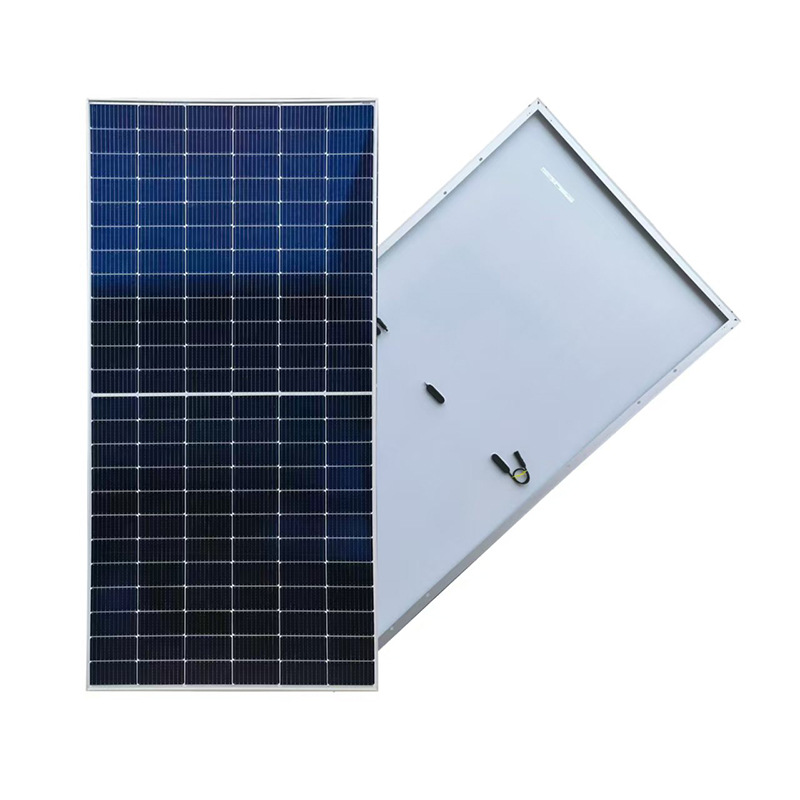

Module Composition

Composed of dozens of solar cells, junction boxes, and frames. Multiple individual cells are connected in series and parallel, and hermetically sealed into a module to form an independent power generation unit that can provide DC output. It also includes frames and encapsulation materials, such as textured tempered glass, PET backsheets, EVA, etc.

Structural Technologies

Half-Cell Technology:

A cell is cut into two pieces and then reassembled into a photovoltaic module, which can reduce resistance loss and improve module efficiency and reliability.

Shingled Technology:

A cell is cut into five to six small strips, and multiple small cell edges are overlapped and assembled with conductive adhesive, which can increase the module's packing density and power.

Flexible Module Technology:

Also called lightweight modules, can be bent and are suitable for installation on curved roofs. One type replaces the glass panel with a flexible panel based on shingled photovoltaic module technology, and the other uses thin-film cells.

Product Parameters

Taking a 540W monocrystalline shingled module as an example:

Operating voltage: 40V

Operating current: 13.77A

Short-circuit current: 14.43A

Power tolerance range: -3% to +3%

Can withstand wind load of 2400 Pa and snow load of 5400 Pa

Operating temperature range: -40℃ to 85℃

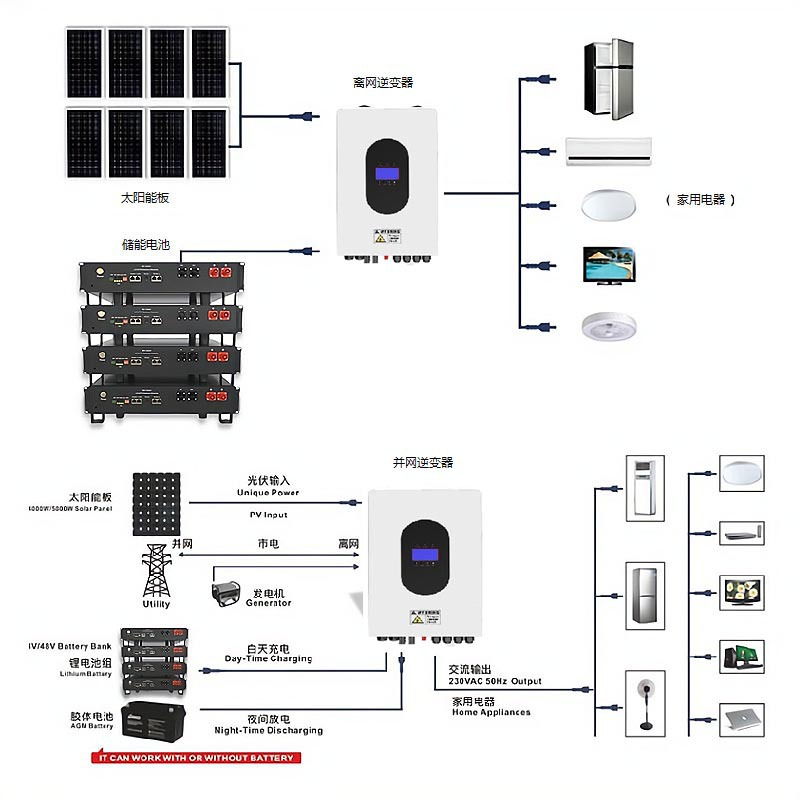

Application Scenarios

Can be installed on rooftops and building surfaces, as part of windows, skylights, or shading devices, to form building-integrated solar systems. Widely used in independent power generation systems to supply electricity to remote households, base stations, etc.; also used in grid-connected power generation systems, such as for industrial and commercial users and residential buildings, to reduce electricity costs and dependence on traditional energy sources.